- Ready to use .gcode files for Prusa MK3S Style printers

- .3MF files for Bambu Studio

- .3MF files for Prusa Slicer

- .STL files for use with any slicer of your choice.

- .STP files for customizing setup-specific parts.

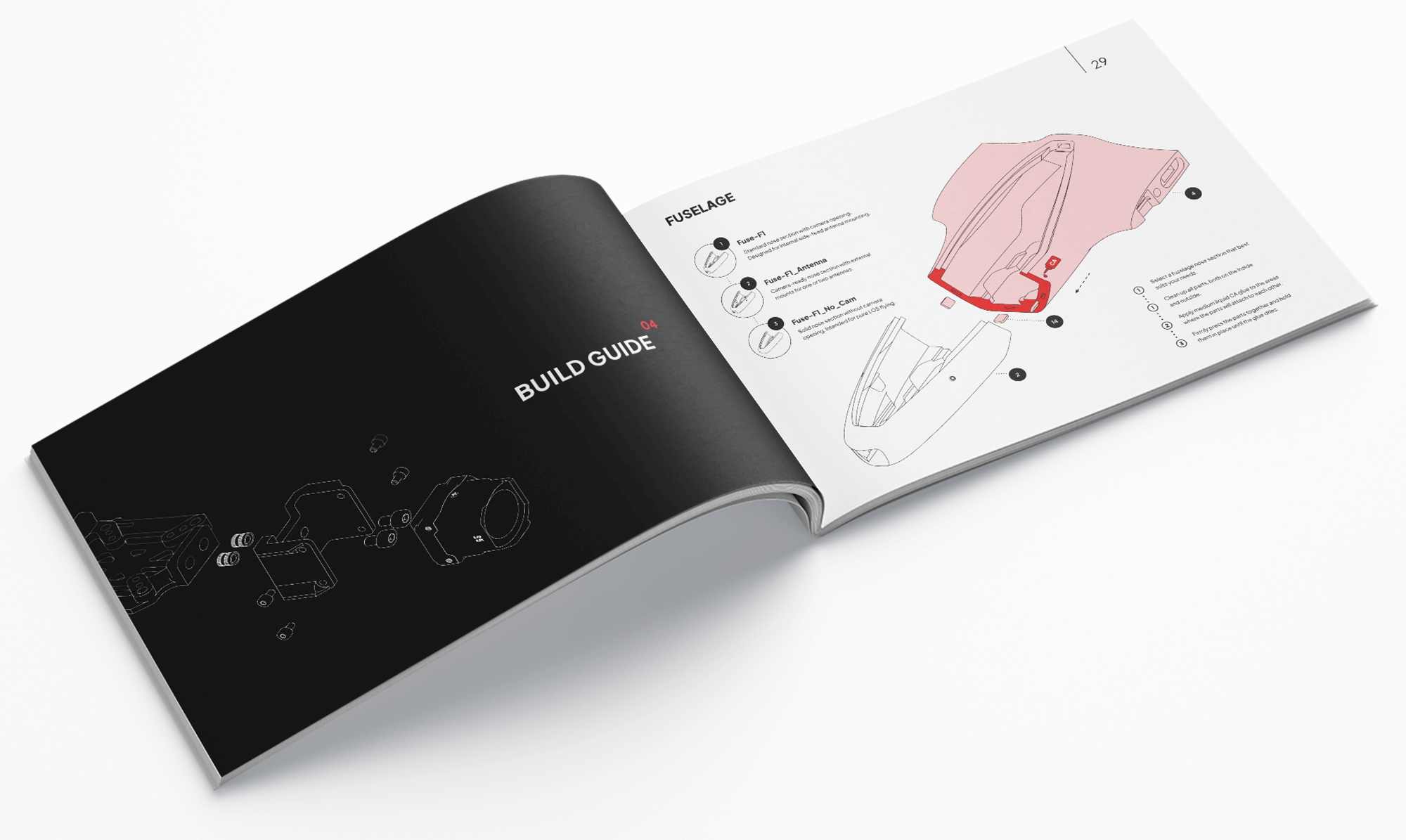

- User Guide (Detailed for assembling and printing)

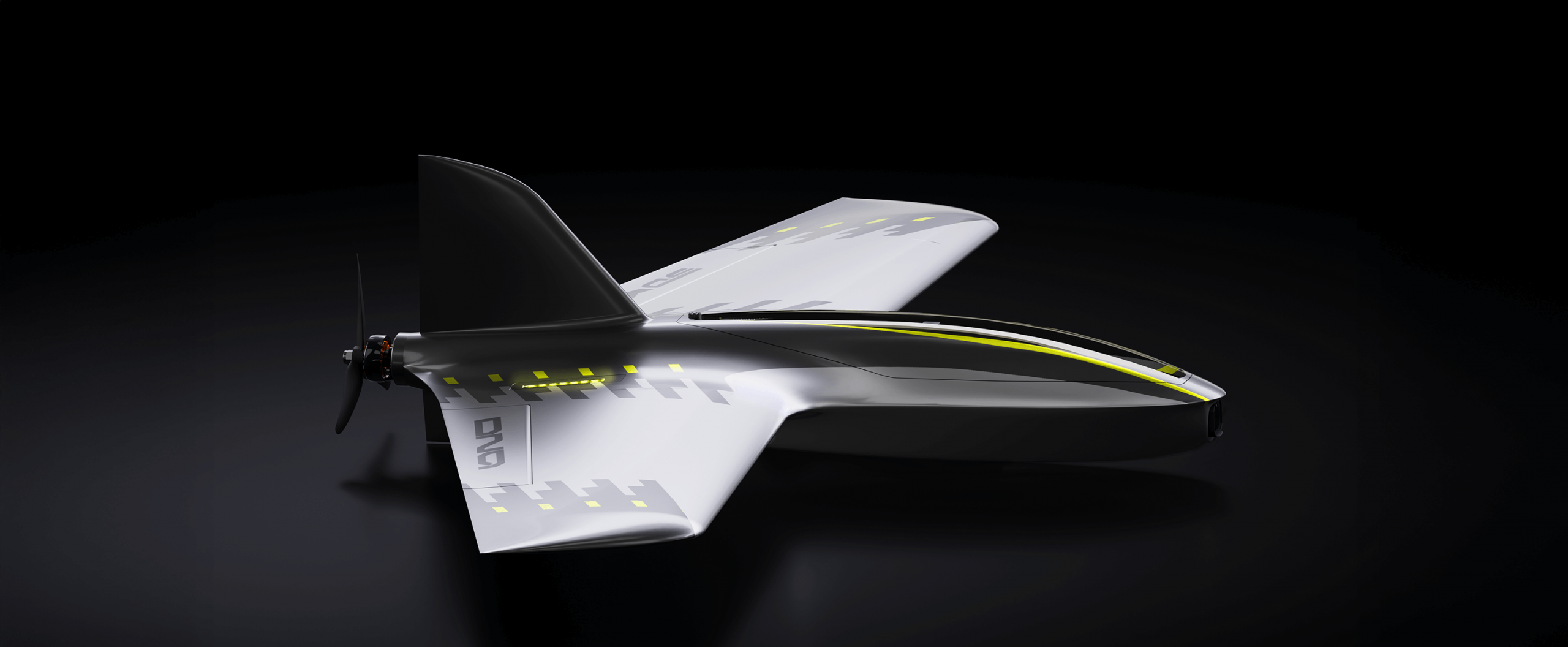

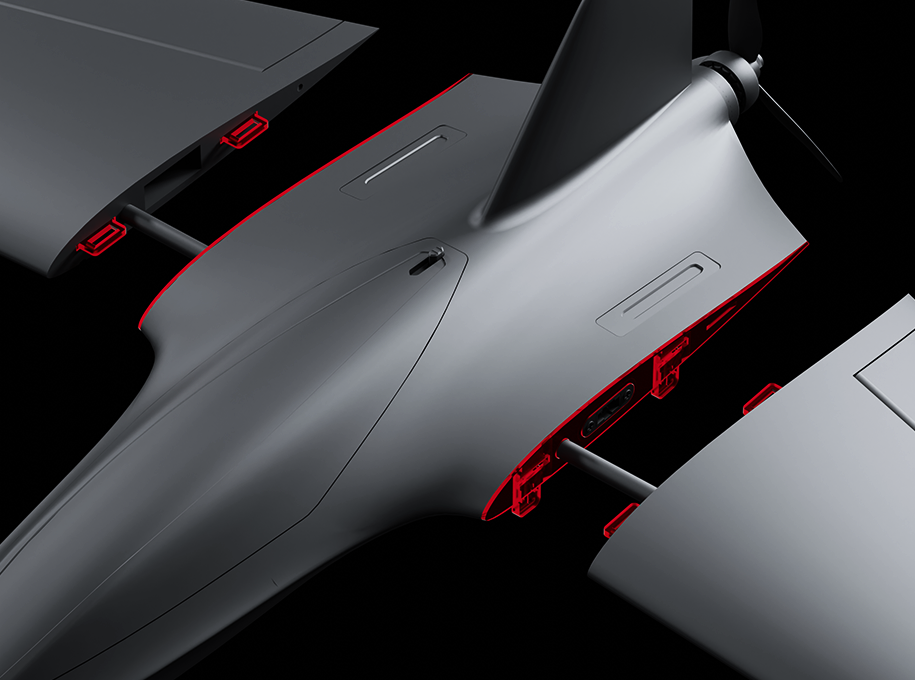

DNA 3D printed FPV Wing

29.99 €

*Values may differ depending on the used setup.

DNA

The DNA is a compact, 3D-printed 800mm FPV wing engineered for pilots who want a fast, intuitive transition from quads to fixed-wing flying. Its infill-based 3D-print construction keeps the build simple, durable, and easy to repair, while the efficient aerodynamic design delivers smooth cruising and the power to push up to 230 km/h when you let it rip.

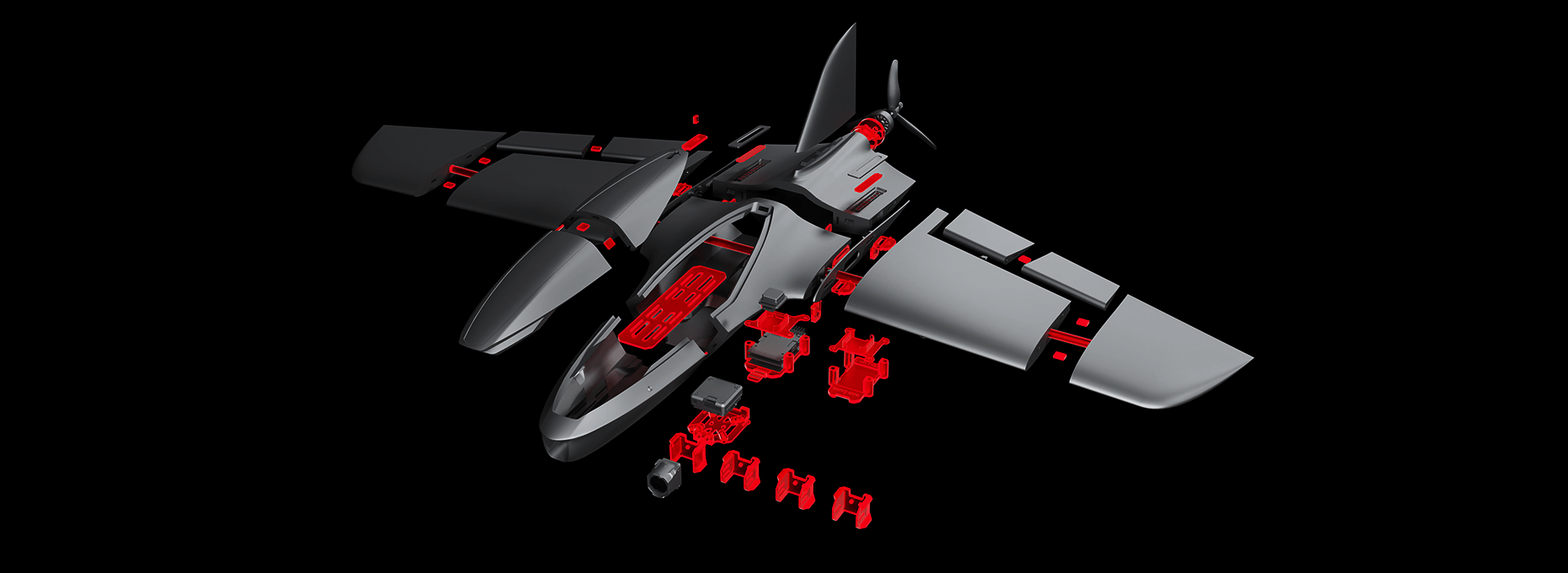

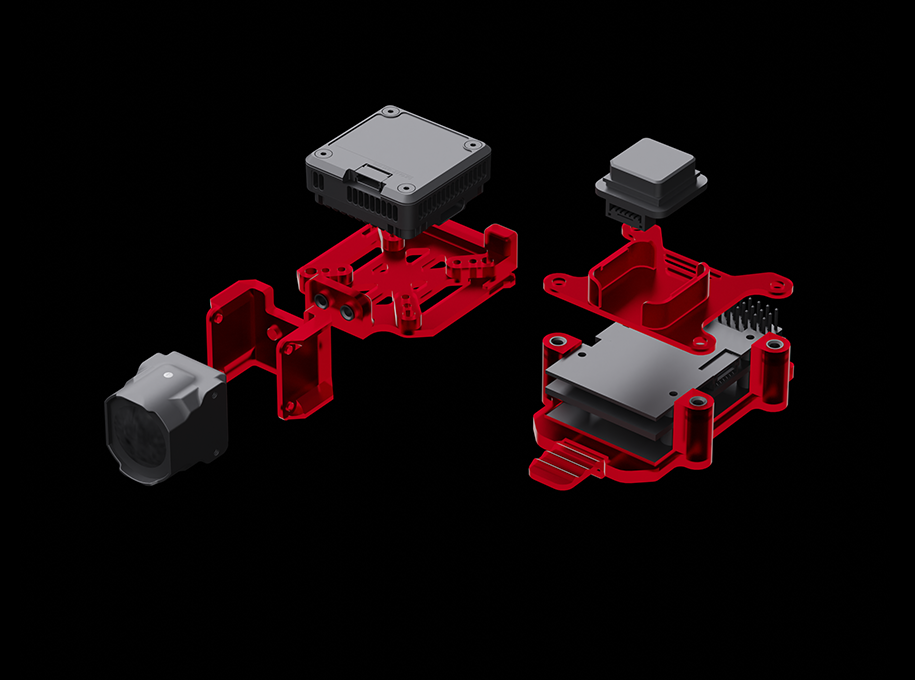

Optimized for modern digital FPV systems, the DNA supports 20mm, 25.5mm, and 30.5mm mounting patterns, giving pilots maximum flexibility for their preferred stack configuration. A range of dedicated camera-mount options ensures compatibility with popular digital FPV cameras. Thanks to its quick-lock wings and modular quick-swap electronics, the DNA stays ultra-portable and allows fast, effortless maintenance or component changes.

With its crisp handling, strong efficiency, and compact footprint, the DNA excels at tight proximity lines, high-speed passes, and relaxed cruising alike. It’s a travel-friendly, high-performance FPV wing designed around the gear pilots already trust — fully 3D-printable and ready for adventure.

Download includes

Specifications

- Printed Weight: 330 g

- Take-Off Weight: 650 g

- Stall Speed: 28 km/h

- Wing Span: 800 mm

- Wing Loading: 46.6g/dm²

- Wing Area: 13.95 dm²

- Length: 538 mm

Instruction Manual download

Download our latest manual, which includes all building steps and basic setup information. We continuously update our manuals, so be sure to check back regularly for the latest version.

Packed with

Features you love

Compact Size, Big Performance

Compact Size, Big Performance

An 800mm footprint paired with an efficient forward-swept design delivers crisp handling, tight turns, and thrilling speed—perfect for quad pilots transitioning to wings.

Built for Modern FPV Gear

Built for Modern FPV Gear

With universal 20mm, 25.5mm, and 30.5mm mounts, the DNA seamlessly fits today’s popular FPV stacks without adapters or hacks.

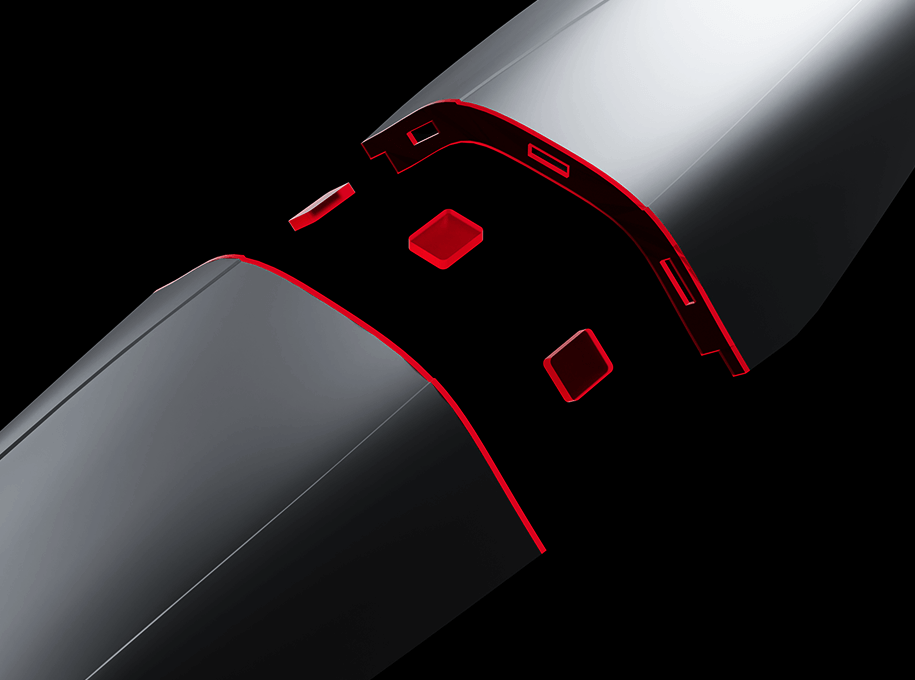

Quick-Lock Everything

Quick-Lock Everything

Tool-free wing mounts and modular electronics let you pack, prep, and swap components with minimal effort—so you spend more time flying and less time fiddling.

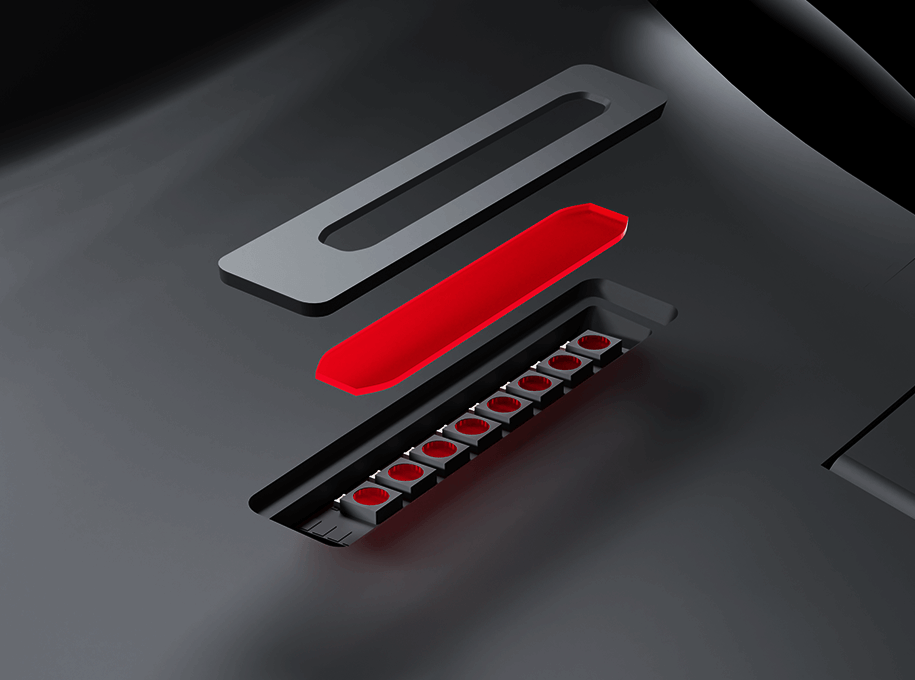

LED Support

LED Support

Built-in routing and mounting points make it easy to add WS2812 LED strips, giving your DNA enhanced visibility and customizable lighting for low-light conditions.

Built-In Alignment

Built-In Alignment

Every major component includes integrated alignment tabs, ensuring precise assembly and a clean fit—no guesswork required.

Infill-Based

Infill-Based

Light, durable, and easy to repair—thanks to its infill core. Choose your own infill type and density to strike the perfect balance between strength and weight.

Fast to print. Fast to build. Fast to fly.

The 3DBlackbox DNA is a modern 3D-printed fixed-wing designed for FPV and LOS pilots who want performance without complexity. Its compact 800 mm wingspan, print-friendly structure, and modular quick-lock design make building, tuning, and maintaining the aircraft simple and intuitive.

The build video and instruction manual guide you step by step through the process, helping you get from printer to first flight quickly — whether you’re transitioning from quads or looking for a fast, everyday FPV wing.

You got questions?

Is it possible to upscale or downscale models?

You can upscale or downscale our models, but modifications might be necessary because our planes are designed for a specific size. Scaling can affect various aspects such as tolerances, servo pockets, motor mounts, and carbon spars. Additionally, the structural design might not withstand the increased forces when upscaled or could result in a heavier plane when downscaled. Therefore, it’s not recommended or advisable to scale the models unless you are prepared to make significant adjustments.

Is it possible to use regular PLA instead of LW-PLA?

If both materials are suitable for printing a specific plane, it will be clearly stated. Generally, using LW-PLA is preferred because it is lighter, which enhances performance in most cases. This is especially important for 3D aerobatic planes where minimizing weight is critical. However, some planes can be printed with other materials as well. Just ensure that you can still achieve the correct center of gravity (CG).

Are soft LW-PLA parts considered normal?

Yes, some parts might feel soft individually. However, once they are glued together, the overall structure will be strong. All our planes are tested for durability and can handle high-G maneuvers without any issues.

What should I do if the ribs aren't connecting to the outer surface?

If you notice that the ribs aren’t connecting properly when using LW-PLA, you should calibrate your printer according to the instructions provided with the download files. This issue could be caused by high temperature, low flow, fast printing speed, or an uncalibrated extruder. If you’re using regular PLA, increasing the flow might resolve the issue.

How can I minimize Z-wobble on tall parts?

Bed slinger 3D printers often experience Z-wobble due to the large moving mass, which creates more vibrations. To reduce Z-wobble, try lowering the print speed for thin and tall parts and ensure the part adheres well to the bed. Increasing the number of brim walls can also help.

Stay up to date with our future projects and developments.

Be the first to hear about our upcoming projects and to see our continuous development! Thank you for your support! Your help makes the future a reality.